In this article, we will discuss what a cream separator is, its purpose, and how it works. We will also go over the best cream separator machines on the market.

Scroll down to learn about each aspect in detail.

What Is a Cream Separator?

A cream separator is a machine that removes and separates the cream from whole cream.

The working principle of a milk cream separator is based on the fact that cream is lighter than skim milk.

Modern cream separators are automated and have the capability to produce milk of any fat content.

At a milk production plant, the cream is separated from the milk via a process called centrifugation. The milk is placed in a large bowl and rotated at a high speed until the cream is eliminated. This is what exactly a cream separator does.

A milk separator also acts as a clarifier because all the unnecessary particles that are heavier than skim milk (e.g. bacteria, sediment, somatic cells) are collected in pockets outside the separator.

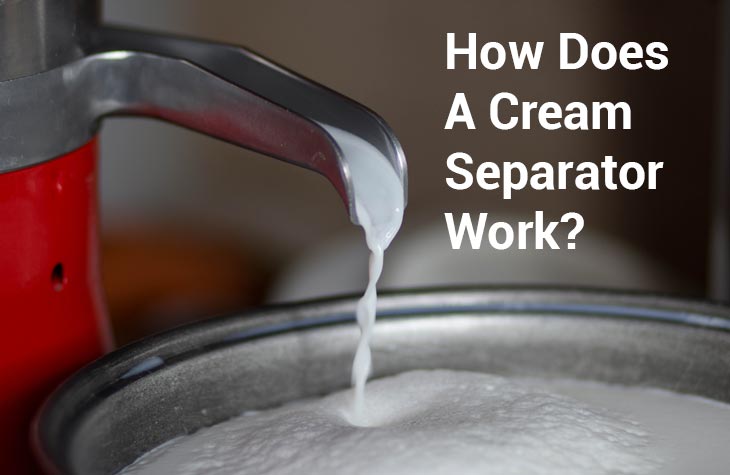

How Does It Work?

Did you know that grocery store milk is homogenized? This means you cannot remove the cream from it. In the production process of milk, its fat globules are broken down to ensure that the particles amalgamate with the milk and don’t float on top.

But if you receive milk straight from a cow, skimming the cream is a hassle. It requires patience and dedication. How do you make cream from milk? A cream separator is the most convenient and reliable tool to skim cream.

How does this machine work? A milk separator uses centrifugal force, rotating the milk at high speed.

The milk moves through the conical disks with a force equivalent to thousands of times the gravitational force.

Since the fat globules are the lighter part of the milk, they move to the drum’s heart, while the heavier skim milk goes to the sides as it separates from the fat. The whole process is dubbed cream-skimming.

Why Use a Cream Separator?

How do you separate cream from milk? Using a cream separator based on the principle of centrifugal force is the modern way to make cream from milk. It is a fantastic device that removes the cream from cow/goat/camel/sheep/etc. milk. How is cream made from a cream separator? Operating a milk separator is easy. You do not need any professional training.

Once you read the manual and understand the different buttons as well as their functions, you are ready to separate the milk.

A cream separator is a preferred choice if you are producing dairy milk and skim milk in bulk. The different components of a cream separator are durable and straightforward to clean.

How Does a Centrifugal Separator Work?

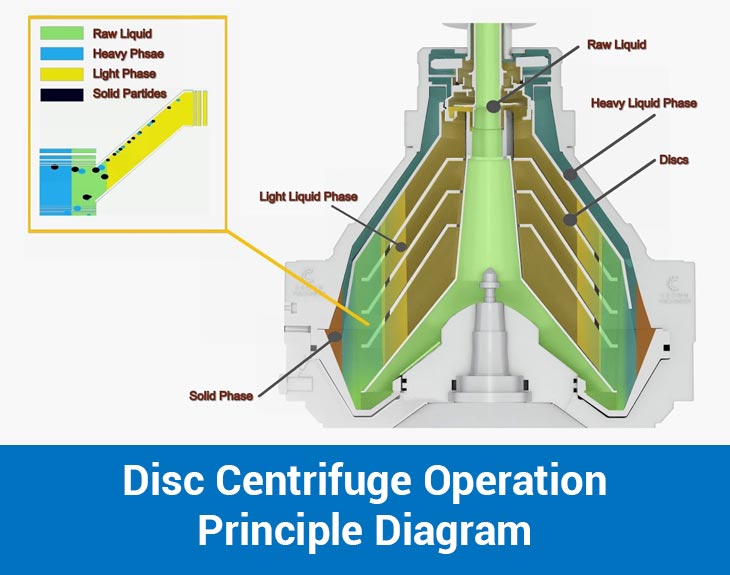

As discussed earlier, a centrifugal milk separator operates on the power of centrifugal force. Such a separator is popularly known as a centrifugal separator.

Now, let’s understand how it works. Centrifugal force is generated whenever a vessel that is filled with liquid (e.g. milk) is spun.

This is why a centrifugal separator is also called a disc bowl separator. The field creates centrifugal acceptation, and this isn’t as steady as gravity.

A centrifugal milk separator has baffle inserts in the form of conical discs. This increases the area of sedimentation.

When whole milk is inside the bowl, the centrifugal force runs through the baffle inserts, and the heavier part (e.g. cream) is separated. After the process, the milk and cream flow out of different spouts.

10 Best Cream Separator Machines on the Market

Are you considering investing in a cream separator machine but are baffled by the number of options on the market? Do not worry. In this article, we have rounded up the top-selling cream separators on the market.

Read on for more information about each one.

#1 Motor Sich 100-18

Who doesn’t want a cream separator that can output as much as 100 liters per hour? This machine also ensures a minimal fat content of 0.005%.

What’s remarkable is that it offers one hour of continuous operation. The only drawback is that the machine is heavier in its segment.

#2 Motor Sich 100-19

Motor Sich has manufactured an electric cream separator made of food-grade polycarbonate, thus ensuring healthy output every time.

The Motor Sich electric milk separator can skim milk from cows, goats, sheep, camels, and more. It has a capacity of 100 liters per hour. The Ukrainian motor comes with brushes that make it ideal for commercial use.

The only flaw we could find with this machine is that the polycarbonate structure makes it slightly heavier.

#3 Milky FJ 90 PP

Your search for the best cream separator that is most efficient and easy-to-operate will end with the Milky FJ 90 PP. It gives an output of 80-100 liters/hour. The Milky FJ 90 PP mortar is durable, and the parts don’t rust with time. The components are made out of food-grade materials.

#4 Milky FJ 130 ERR

With an hourly output of 34 gallons per hour, this cream separator is insane. It has anodized aluminum disks for super durability. It is best suited for commercial use, separating anodized aluminum disks cream, sour cream, and low-fat milk. This machine is easier to operate, and the parts can be quickly assembled and disassembled.

#5 Elecrem No.1 Cream Separator

The only flaw we could find with this machine is that the polycarbonate structure makes it slightly heavier.

Elecrem No.1 is an electric cream separator capable of generating tremendous speed to provide a good output compared to other models on the market. It ensures a thorough separation of cream and milk, delivering the finest-quality milk for consumption.

The machine can separate 125L of milk per hour and comes with a 10L capacity reservoir tank. It requires a voltage converter for use in the USA and Canada.

#6 Penzmash ESB 02

If you are searching for an affordable cream separator that skims 50 liters of milk per hour, the Penzmesh Cream Separator is a good choice. It has a durable construction. You do not need to worry about wear and tear.

This machine is straightforward to use. You will master its basic functionality in no time.

#7 Motor Sich 80-09

With 0.05% max fat in skimmed milk, this Aluminum alloy provides 80 – 100 liters/hour of output per hour. This hand-operated Motor Sich milk separator is preferred for regions with electricity issues. T8. Penzmash R3-OPS. Using this manually operated machine, you can make sour cream, and low-fat milk at home. This product is a perfect blend of quality and affordability.

The only drawback is that you will have to rotate the bowl by hand, so be ready to flex your muscles.

#8 Penzmash R3-OPS

This cream separator made with a maximum of 0.05% fat is suitable for both domestic and commercial use. Made of high-quality materials (aluminum alloy), this machine provides great durability.

From the installation to the usage, this milk separator offers real convenience.

The machine stays stable during operation. However, it is not the lightest milk separator on the market.

#9 Minneer Milk Cream

This stainless cream separator is versatile and convenient to use. The machine is fully automatic. Just switch it on, and it will start the cream separation with no manual effort.

It can skim 21 gallons of milk per hour. The various parts of this machine are slightly difficult to clean.

#10 Motor Sich 100-18 Chinese Caunterfake

Last on the list is the Motor Sich 100-18 cream separator.

It has a strong construction, as the parts of this cream separator machine are made out of good quality materials for excellent durability. So, it can handle rough and tough use. The installation process is a walk in the park (5-10 minutes).

Wrapping Up

Before making a purchase, it is of paramount importance to research the cream separator’s manufacturer and its market credibility. There are endless options for cream separators on Craigslist, but you should opt for one that is made of high-quality, food-grade material. It must be light in weight and therefore convenient to transport from one location to another.